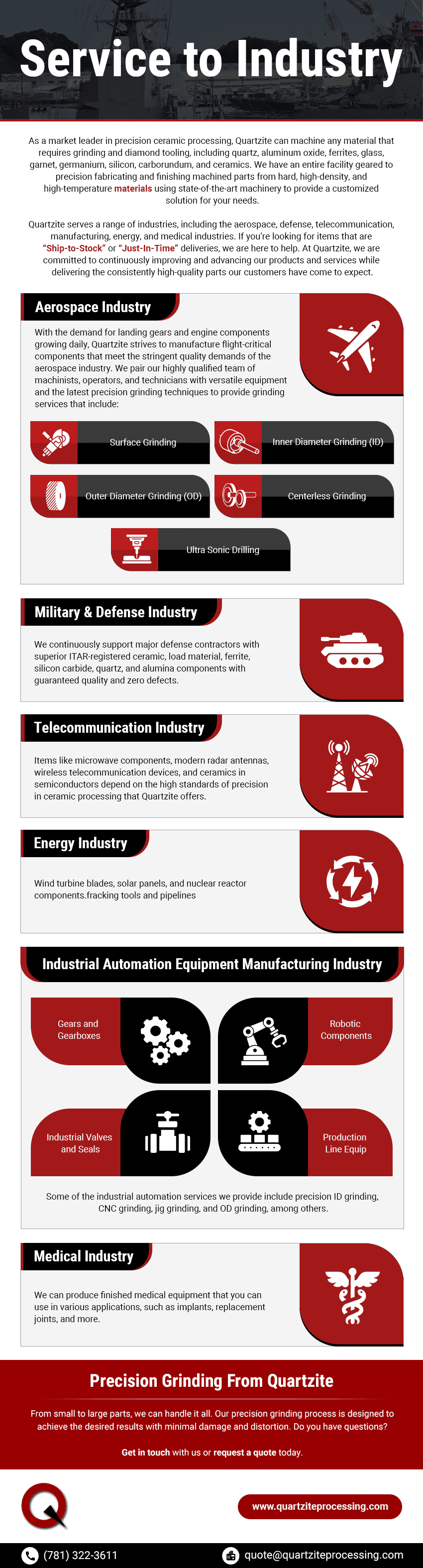

Service to Industry

As a market leader in precision ceramic processing, Quartzite can machine any material that requires grinding and diamond tooling, including quartz, aluminum oxide, ferrites, glass, garnet, germanium, silicon, carborundum, and ceramics. We have an entire facility geared to precision fabricating and finishing machined parts from hard, high-density, and high-temperature materials using state-of-the-art machinery to provide a customized solution for your needs.

Quartzite serves a range of industries, including the aerospace, defense, telecommunication, manufacturing, energy, and medical industries. If you’re looking for items that are “Ship-to-Stock” or “Just-In-Time” deliveries, we are here to help. At Quartzite, we are committed to continuously improving and advancing our products and services while delivering the consistently high-quality parts our customers have come to expect.

Aerospace Industry

With the demand for landing gears and engine components growing daily, Quartzite strives to manufacture flight-critical components that meet the stringent quality demands of the aerospace industry. We pair our highly qualified team of machinists, operators, and technicians with versatile equipment and the latest precision grinding techniques to provide grinding services that include:

- Surface grinding

- Inner diameter grinding (ID)

- Outer diameter grinding (OD)

- Jig grinding

Military & Defense Industry

The military and defense industry uses complex weapons and machinery that require high-precision ceramic grinding. At Quartzite, we go far and beyond to meet the high-standard requirements of this field. We have been a trusted supplier of parts for missiles, radar, and other electronic systems for over 65 years. We continuously support major defense contractors with superior ITAR-registered ceramic, load material, ferrite, silicon carbide, quartz, and alumina components with guaranteed quality and zero defects.

Telecommunication Industry

More advanced communication materials made through precision grinding are in demand in the growing field of telecommunications. Items like microwave components, modern radar antennas, wireless telecommunication devices, and ceramics in semiconductors depend on the high standards of precision in ceramic processing that Quartzite offers.

In 1962, Bell Telephone Systems turned to Quartzite to help them process materials crucial in manufacturing Telstar, the first satellite capable of transmitting telephone, data, and TV messages across the ocean. At the time, Quartzite was one of the few companies that could process materials accurately and quickly enough to meet the growing satellite industry’s needs, which has not changed since.

Energy Industry

In the energy industry, precision grinding helps to create various power-generating products that require high accuracy, making it an essential process. These products include wind turbine blades, solar panels, and nuclear reactor components.

Quartzite’s precision grinding services are also used to create products used in the oil and gas industry, such as fracking tools and pipelines. With the level of precision we offer, we provide the energy industry with safe products that meet industry-specific requirements, making Quartzite essential in their operations.

Industrial Automation Equipment Manufacturing Industry

In the industrial automation equipment manufacturing industry, precision grinding is essential for creating highly accurate, repeatable products. We can produce a range of tight-tolerance components for this industry, including:

- Gears and gearboxes

- Robotic components

- Industrial valves and seals

- Production line equip

- And more!

At Quartzite, we use precision grinding to create reliable, durable products that are resistant to wear and tear. Some of the industrial automation services we provide include precision ID grinding, CNC grinding, jig grinding, and OD grinding, among others.

Medical Industry

The medical industry requires precision grinding for several reasons. First, the human body is an intricate system of moving parts, and any surgical intervention requires precision to minimize the risk of damage to healthy tissue. Additionally, many medical instruments are made of extremely tough materials that can only be machined using precision grinding techniques.

Our in-depth precision and high-quality grinding standards at Quartzite allow us to produce finished medical equipment that you can use in various applications, such as implants, replacement joints, and more. We employ in-depth inspection procedures on all medical components to ensure quality and meet regulatory standards.

Precision Grinding From Quartzite

With over 65 years of experience, we can perform even the most demanding grinding tasks. From small to large parts, we can handle it all. Our precision grinding process is designed to achieve the desired results with minimal damage and distortion.

Do you have questions? Get in touch with us or request a quote today.