Quartz pressure windows feature unique characteristics that make them well-suited to challenging environmental conditions. However, machining quartz glass requires specialized equipment and technical expertise. This blog will discuss quartz glass properties, uses for quartz, and how Quartzite Processing Inc. processes this material.

What are Fused Quartz Windows?

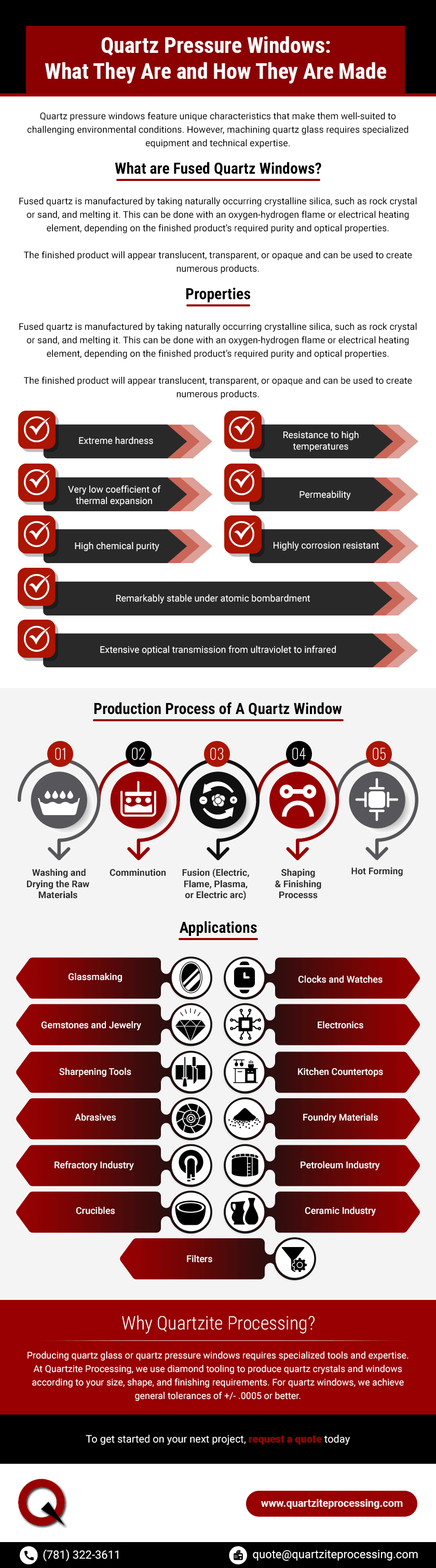

Fused quartz is manufactured by taking naturally occurring crystalline silica, such as rock crystal or sand, and melting it. The crystalline silica, or quartz sand, can be melted using multiple methods. Depending on the finished product’s required purity and optical properties, either an oxygen-hydrogen flame or an electrical heating element is used to melt the raw materials.

Afterward, the finished product will appear translucent, transparent, or opaque and can be used to create numerous products. Fused quartz features high-temperature stability up to 1050 °C and is highly resistant to thermal shock. It is also very durable and chemical resistant.

Properties

Fused quartz features numerous notable properties, including:

- Extreme hardness

- Resistance to high temperatures

- Very low coefficient of thermal expansion

- Permeability

- High chemical purity

- Highly corrosion resistant

- Remarkably stable under atomic bombardment

- Extensive optical transmission from ultraviolet to infrared

Production Process of Quartz Window

Producing quartz glass begins with melting exceptionally pure natural quartz crystals. These crystals feature an SiO2 content of 99.9%. The material has particularly low potassium, sodium oxides, and iron content, resulting in a very low overall trace element content. After the crystals are melted, they are allowed to cool in the desired dimensions and shape.

Producing quartz windows requires several steps:

- Washing and drying the raw materials: To begin, all dirt, contaminants, and moisture are removed from the natural quartz. This is a necessary step if working with mined quartz.

- Comminution: Next, raw quartz crystals are reduced to a size suitable for fusion. This can involve crushing or milling.

- Fusion: Using high temperatures, thermal energy breaks the silicon-oxygen bonds, creating a less viscous flow of quartz. Depending on the required purity of the end-use application, one of several fusion methods can be used: electric, flame, plasma, or electric arc fusion.

- Electric fusion: This method is used to produce Type I quartz glass with high purity levels.

- Flame fusion: This method produces Type II quartz glass that has a lower operating temperature and lower temperature softening point.

- Plasma fusion: This method produces highly pure quartz glass with minimal bubbles and no drawing lines. Plasma fusion uses a water-vapor free plasma flame as the heat source.

- Electric arc fusion:This process creates an opaque end product, with microbubbles that diffract light. It uses an electric arc furnace to heat quartz sand.

- Shaping and finishing processes:After the quartz is melted, it is shaped and formed. This process requires diamond cutting tools due to the hardness of the quartz. Finishing processes include grinding, drilling, and cutting.

- Hot forming: Quartz glass needs to be at a certain temperature to be shaped. To prevent low temperatures from occurring, hot forming methods can be used. These include welding, collapsing, compression and elongation, and glass blowing.

Applications

Fused quartz glass is used throughout numerous industries and produces many widely used consumer goods. Some of the most common applications of quartz glass include:

- Glassmaking

- Clocks and watches

- Gemstones and jewelry

- Electronics

- Sharpening tools

- Kitchen Countertops

- Abrasives

- Foundry materials

- Refractory industry

- Petroleum industry

- Crucibles

- Ceramic industry

- Filters

Why Quartzite Processing?

Producing quartz glass or quartz pressure windows requires specialized tools and expertise. At Quartzite Processing, we use diamond tooling to produce quartz crystals and windows according to your size, shape, and finishing requirements. For quartz windows, we achieve general tolerances of +/- .0005 or better.

Quartzite Processing is equipped to handle quartz machining projects of any size. We maintain a wide inventory and offer specialty ship-to-stock and just-in-time delivery services. We are dedicated to maintaining the highest quality standards and are ITAR as well as ISO 9001:2015 certified.

With turnaround times of as little as seven days, we can quickly meet your application’s needs. You can learn more about our quartzite processing capabilities here, and reach out to us with any questions. To get started on your next project, request a quote today.